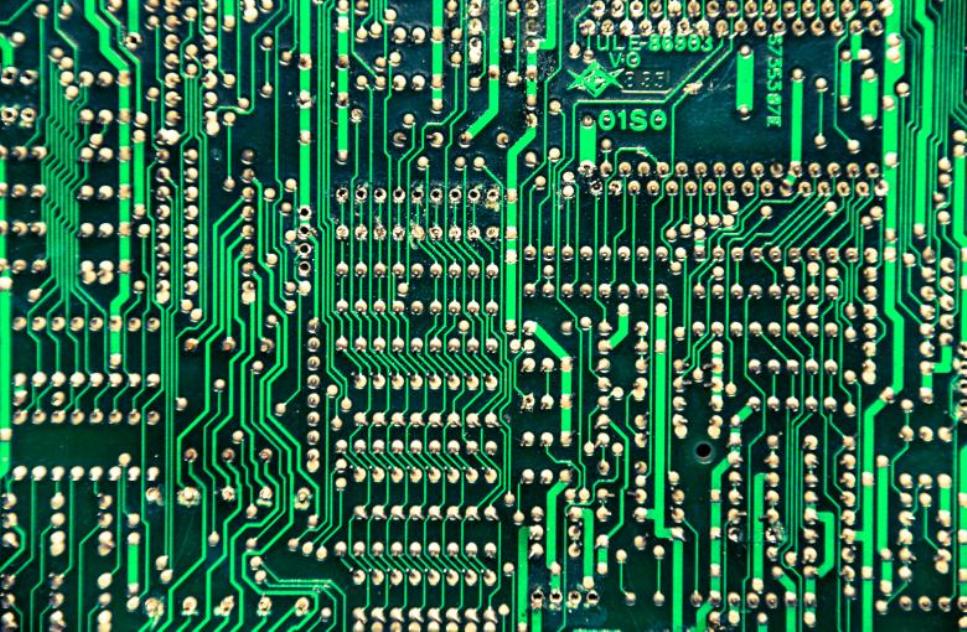

An Overview of Printed Circuit Boards

See how PCBs have developed and how they're used in modern technology. Also check out how they've developed in recent years and what they're looking to do in the future.

Join the DZone community and get the full member experience.

Join For Free

A printed circuit board or PCB is a think board used to connect electrical components using copper tracks instead of wires. Holes are drilled in the board and these are used to fix electrical components in position. They are then soldered to secure their position and the copper tracks link them together forming a circuit. The board and the components combined together are known as a PCB assembly (or Printed Circuit Board Assembly).

The first printed circuit boards (PCBs) can be traced all the back to the early 1900s and a patent for “printed wire.” It was in 1925 that Charles Ducas first submitted a patent that involved creating an electrical path directly on an insulated surface. It was a revolutionary idea because it could eliminate complex wiring and provide consistent results. Still, they didn’t really catch on until after WWII, when Dr. Paul Eisler in Austria began making the first real operational printed circuit boards in 1943.

Today, printed circuit boards have evolved and become part of our modern day technology. Whether you are wearing a fit-bit, watch or using an iPhone, the list can go on and on, you are benefitting from their sophisticated, delicate design that keeps the gadgets we depend on running smoothly. The most exciting part is that these advancements show no signs of slowing down and guarantees new ways that will continue to improve our quality of life and enjoyment of gadgets we can no longer live without!

Just imagine what’s to come in the future as we continue to exploit the untapped potential of the world’s technology.

Types of PCB boards

There are basically three types of printed circuit board (PCB) structures. They include:

Flex

Rigid flex

Rigid

Flex

Flexible PCBs present the perfect solution to creating reliable and repeatable interconnections between electronics boards. They allow for complicated interconnections to be printed rather than made using discrete conductors. The result is a greatly reduced level of complexity in device assemblies and more reliable operation. Flexible PCB designs can also be very complex, with very high signal trace densities and multilayer configurations available to designers.

Rigid Flex

Flex-ridged designs allow for an interconnection flexible PCB to be permanently connected to a rigid multilayer PCB board. This type of configuration is used when a design calls for very complex PCB, but the designer wants to reduce the complexity of final product assembly by including the flexible interconnection PCB in the fabricated PCB. As such, using a flex-ridged PCB allows for the complete design to be ready upon receipt from the fabricator. Flex-ridged designs also allow for the creation of three dimensional designs and can include multiple rigid and flexible sections.

Rigid

Rigidzed flexible PCBs allow for the use of flexible PCB for the majority of a design while protecting a section of the PCB design that is not intended to be bent. This is of great benefit when you want to use a flexible PCB as the basis of your design. Often flexible PCBs are designed to include surface mount devices in a portion of the flexible board. This section will then be reinforced with a rigid backing to protect the ICs from flexing during use. Flexible PCBs are also much lighter and can fit into tighter housing than their traditional counter parts. Using flexible PCBs, three-dimensional designs can also be accommodated in a single PCB. When size and weight are a point of emphasis, flexible PCBs are a great starting point.

The demands for smaller, cheaper, faster circuit boards have made it challenging for the PCB designers and these types of boards are built to soothe the variety and taste of the consumers/customers.

Advances in PCB Boards

Advances in technology have given rise to electronic gadgets. IPods, computers, laptops, radios, and many other electronic gadgets that we enjoy every day are products of advances in technology. Today, durable materials, high aspect ratio holes, and other features are combined with the different electronic companies to provide gadgets for the public.

Electronic gadgets today use printed circuit boards (PCBs) in order to function efficiently. PCBs are specially designed depending on what type of devices they are going to be used. Computers, radios, guitar effects, and many other electronic gadgets have utilized PCBs in order for them to perform all of their functions. These boards (PCBs) serve as the brain box of most gadgets as devices such as phones, computers, alarm systems etc. will not work without them.

Today, the printed circuit board industry has evolved. Most new PCBs have extra features in order to efficiently make electronic gadgets perform better. Today, PCB manufactures offer plates with high-aspect ratio holes. Signal and frequency are necessary in the function of PCB, and high-aspect ratio holes create a more uniform flow of electrolytes to different destinations in the panel. This improves the functionality of different components in the board.

Manufacturers have also heavily invested in using high-frequency materials to mitigate signal loss when using PCBs. Choosing the right materials for a PCB will determine the quality of electronic devices. For radios, oscilloscopes, and other devices that depend on frequency, using the right materials mean greatly improved functionality. If one is looking for quality PCBs and materials, it's possible to contact one of the many manufacturers in the PCB industry.

There are many PCB classifications based on their quality and performance. Today, one of the most sophisticated PCB classifications is the IPC-6012 Class 3. It follows many IPC standards in order to better function for different, complex circuitry of different types of devices. Complex circuit boards like the IPC-6012 Class 3 are demanded today, since it complies with many industry standards. Quality in the realm of PCBs is deeply needed, since any small flaw in it may cause the circuitry of a device to short and may lead to different hazards and injuries.

From the computers used in offices to the radios used by people at home, they are all made up of complex circuitry embedded in printed circuit boards. It is best for electronic manufacturers to use PCBs like the IPC-6012 Class 3 to ensure minimized signal loss and clarity in frequency when transmitting signals throughout these devices. Today, PCB manufacturers are currently developing more features to add to their products to further improve the performance of electronic devices.

The methods by which printed circuit boards are made have also changed throughout the years. What used to be a slow and meticulous process is now handled by machines for the most part. Automated and operator-controlled production machinery takes the brunt of PCB manufacturing. Using these methods means that companies don't have to employ quite so many workers to fill orders and can focus on using their funds on research and development to continue finding newer and on research and development to continue finding newer and better ways to make circuit boards.

Better Designs

Smaller circuit boards mean more capabilities in a compact package. Circuit boards can be made in one of three configurations – single layer, double layer, or multi-layer. The more layers, the denser the PCB can be. This can be great for technology that requires a lot of capabilities without sacrificing space in the device. A few examples of where smaller, but denser is better include smartphones, tablets, all-in-one devices, and even wearable or implantable medical devices.

Advances for Circuit Boards Are Far from Over

People are always coming up with better products and improved products, so it would be very surprising if circuit board innovations stopped one day. There will always be a new idea and someone willing to do the work to make it happen. There have been many innovations in PCB materials and processes. The trend is towards high-frequency electronics which provide lower electric losses and higher operation voltages.

The Future

The future of the PCB will more than likely involve six or more layers of thin laminates. Miniaturization of electronic products continue to drive printed circuit board manufacturing technology and design towards smaller and more densely packed boards with increased electronic capabilities. Future advancements may include three-dimensional molded plastic boards and the increased use of integrated circuit chips, POP (package on package) as well as embedded components. These and other advancements will keep the design and manufacture of printed circuit boards a dynamic and constantly evolving industry for many years to come.

Opinions expressed by DZone contributors are their own.

Comments