Design Thinking in Robotic Automation

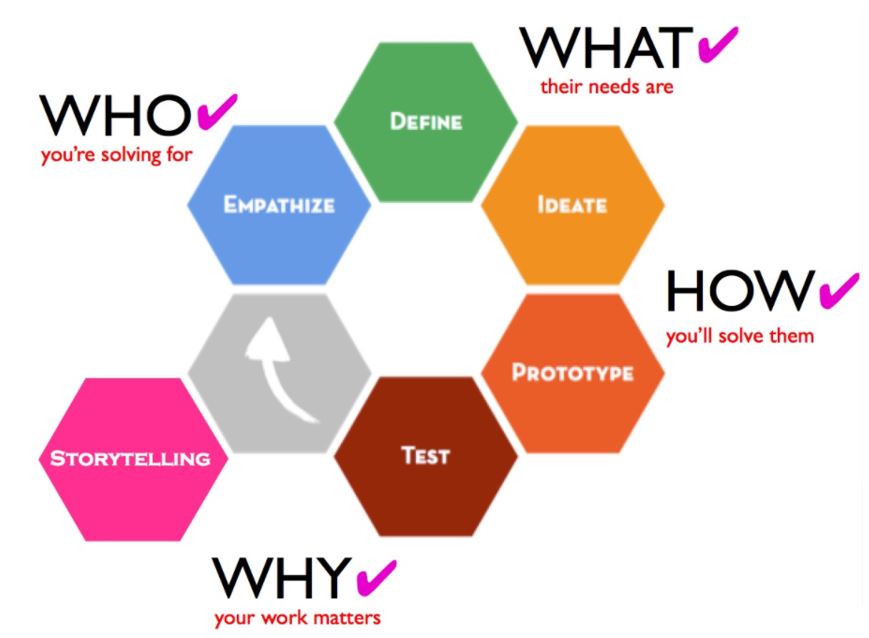

Design thinking is not linear, but it should always involve these 5 steps: empathize, define, ideate, prototype, and build/test.

Join the DZone community and get the full member experience.

Join For FreeDesign thinking has become a buzzword among corporations worldwide today. The need for “out-of-the-box” thinking and constant innovation to beat and not just meet customer expectations is becoming the unwritten aspiration of corporations.

For years, procedural and analytical thinking has been prioritized over creativity at the corporate ivory towers. Products that thrived for decades ruling consumer minds are fast going into oblivion. Organizations that operate with “analytical thinking” are constantly being disrupted by changing trends and customer values. The inability of organizations to rapidly change and succeed can be attributed to the workforce of today, which has imbibed dominant analysis and logic in its actions. This is due to years of rule-driven education and experience that curtained creative thinking.

Design thinking calls for putting the gray cells into action and breaking the barriers of imagination to create products and services that meet unmet needs of discerning customers of today.

So how does design thinking play into the world of bots? Where routine human actions driven by business rules aim to be automated through bots. Merely automating routine activity with no imagination requires no out-of-the-box thinking. Let's understand what “design thinking” is before we delve into its impending need in robotic automation.

“Design thinking can be described as a discipline that uses the designer’s sensibility and methods to match people’s needs with what is technologically feasible and what a viable business strategy can convert into customer value and market opportunity.” – Tim Brown CEO, IDEO

Design thinking will help solve business problems and create solutions that meet customer needs. This mandates a change in a mindset that is solution-focused and action-oriented in achieving desired results. Every robotic automatic journey requires answering what, why, who, when, and how questions. However, answers to these are often lost in executive pitches or PowerPoints. Their relevance in design thinking is often not understood due to a lack of understanding of the discipline and application.

Here's a simple view to design thinking and the connectivity it has with the what, why, who, when, and how that we constantly refer to in robotic transformation programs:

1. Empathize

It starts with consultants understanding the problem. This involves different means including discussing with and observing the people, processes, and tools in action and recording key aspects. Empathizing allows consultants to see the perspective of the users to understand their pain points, experiences, and needs.

Consultants, as part of the robotic transformation journey, need to get an understanding of the business processes and pertinent issues before selecting them for automation. Consultants need to gather all the required details about the processes, gaps, and pain points. Relentless questioning (using the 5 whys technique) helps consultants record relevant issues and frame the problems.

Automation should be an afterthought and not the driving force.

2. Define

During this stage of design thinking, information assimilated as part of the "empathize" stage will be analyzed to crystallize the business problems. This will help start conversations and steer brainstorming in the right direction.

Automating processes through robots requires every minute detail to be understood and noted along with exceptions. Further analysis of information will assist in a deeper understanding of the processes and help frame said and unsaid problems. This facilitates the creation of a platform to discuss the opportunities for improvement or reengineering of processes.

3. Ideate

Information assimilated, dissected, and framed will start the process of ideation of possible solutions to the business problems. Unconstrained thinking and a free flow of ideas to solve business problems are encouraged during this stage. Any barriers of communication will be removed to encourage the team to arrive at a list of possible solutions that can be further validated.

Detailed information on processes along with exceptions, complexity, risks, values, and benefits will help the automation team finalize the automation candidates. Potential process improvement or reengineering options will need to be evaluated before the decision on automation. Discussion on multiple solution alternatives with all quarters of the organization based on vision, strategy, technology landscape, and feasibility will filter the unwanted and leave the others feasible for further exploration. A proof of concept to validate the best possible solution option is initiated next before moving forward with the enterprise scale robotic transformation.

4. Prototype (Proof of Concept)

As part of this phase, a product is built to solve the issues identified that reflects the customer experience. The product will be demonstrated and tested for conformance by the concerned before a decision is made to move forward with full-scale design and product build activities.

Information, analysis, observations, possible solution alternatives, and final solutions provide robotic designers with the required ammunition to create a scaled-down robot. Prototypes are designed and created, taking into consideration ideal scenarios with minimal exception handling capabilities. However, robotic transformations will be successful only when the prototypes created reflect the key features of full-scale bots. Bot design should account for non-functional requirements in design during prototyping, in addition to the process automation requirements to give the users a view of a robot that mirrors a fully powered one. Creating robots during this stage that purely reflect the best possible scenarios with minimal exception handling could create wrong expectations and result in a robot that doesn’t meet customer needs.

5. Build and Test

The final stage of the design thinking process is the realization of the designed solution. The process of designing, building, and testing continues in iterations until the final end product is achieved.

Based on the prototype testing and feedback, the final automation solution is erected in iterations delivering a continuous stream of value. Feedback received as part of releases should form the requirements/alterations in design. The final robot delivered truly must reflect a solution that is built to empathize with the customer process automation needs and pain points.

Is Design Thinking Truly Linear?

The above reflects design thinking methodology that is linear or sequential. However, in the real world, it rarely is. As understanding evolves, designs, prototypes, and bot functions and capabilities change. This change is recurring and reflects the design thinking methodology that is mostly non-linear.

Be it linear or non-linear, the underlying principles of design thinking never change. The objective of design thinking is to move away from procedural and constrained thinking to find innovative ways to solve problems. During robotic engagements, our solutions are often driven by platform capabilities which often bring out “can-do” lists. While these provide a view to the potential solution, the “can't do” is what often brings out the eighth dimension of strategic thinking. This dimension will help explore possibilities of creating bots that not only meet customer needs but exceed them.

Opinions expressed by DZone contributors are their own.

Comments