Role of Data Annotation Services in AI-Powered Manufacturing

Learn how data annotation services enhance AI-powered manufacturing by improving automation, precision, and decision-making, with their key benefits and applications.

Join the DZone community and get the full member experience.

Join For FreeBefore diving deep into how AI/ML is a boon for manufacturers, let’s explore how the industry has evolved. Steam and water-powered mechanics disrupted manual processes, thus filling the demand versus supply gap. The introduction of assembly lines followed, allowing manufacturers to increase output while reducing product prices. Partial automation further empowered the manufacturers with mass production capability.

Finally, the next big breakthrough came with AI and ML, adding intelligence to the automation formula. In other words, AI is at the forefront of industrial revolution 4.0. Not only this, but a strategic combination of AI with new-age technologies such as cloud computing, IoT, robotics, etc., spearheads the manufacturing industry to new heights, making the processes more accurate, efficient, and scalable.

Thus, it is right to say that manufacturers have come a long way — from tackling issues like hazardous floor fires and labor shortages impacting productivity to managing demand and supply and maximizing production without increasing costs. In short, AI has made the manufacturing sector “smart” and resilient!

The latest report states that the global AI in manufacturing market size is expected to surpass USD 230.95 billion by 2034, expanding at a CAGR of 44.20%. From predictive maintenance to automation, AI-powered applications are revolutionizing traditional processes and enabling manufacturers to achieve greater efficiency and scalability. That said, the data annotation process is what makes AI successful in the manufacturing industry.

Understanding Data Annotation in Manufacturing

Data annotation underpins the success of AI initiatives in every industry, let alone manufacturing. It involves tagging data, including text, videos, images, and audio. Accurate and relevant tags, descriptions, and other contextual information are added to raw data to make it comprehensible for machine learning algorithms.

In manufacturing, predictive analytics helps identify potential equipment failures before they occur, minimizing downtime and reducing maintenance costs. Similarly, computer vision systems inspect products on assembly lines with unparalleled speed and accuracy, ensuring adherence to quality standards. These innovations contribute to cost reduction, operational efficiency, and enhanced customer satisfaction. The key to achieving these outcomes is via data annotation services.

These are imperative for AI systems to understand and interpret data and perform the desired actions, such as identifying defects and predicting maintenance needs. At the same time, ensuring the accuracy and quality of data fed into AI systems is important. Otherwise, the model produces unreliable results, undermining its utility in critical applications. In manufacturing, for example, an incorrectly labeled dataset for defect detection leads to the misidentification of defective products.

For AI systems to learn and perform desired actions, training datasets must accurately represent real-world scenarios. The absence of diverse data limits the model's capability to learn, evolve, and make decisions. However, data annotation is not as simple as it may seem. The right techniques and tools must be implemented to ensure that the manufacturing AI system yields the desired results.

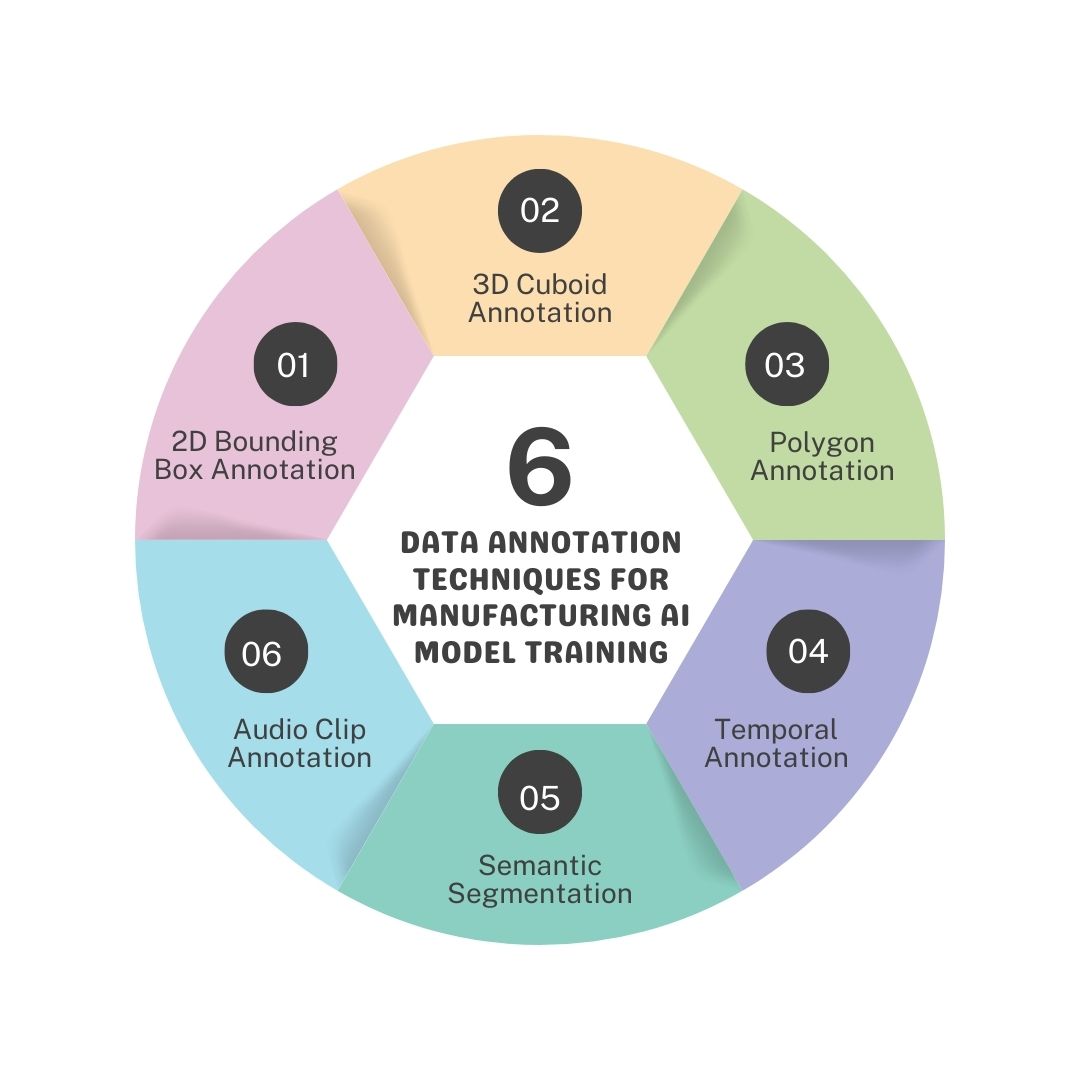

Data Annotation Techniques for Manufacturing AI Model Training

Different data annotation techniques cater to diverse use cases in AI-powered manufacturing where each technique has unique applications, depending on the complexity and specificity of the task. Some of these techniques are mentioned below:

1. 2D Bounding Box Annotation

This technique involves drawing rectangular 2D boxes around objects of interest in images or videos, enabling AI/ML models to identify and localize them. This method is widely used for object detection applications, such as identifying defective products on an assembly line or tracking tools in a workspace.

2. 3D Cuboid Annotation

Unlike 2D bounding box annotation, which involves only the length and breadth of the object of interest, 3D cuboid annotation includes height/depth. This three-dimensional representation of objects offers a more detailed perspective of the AI systems. It is essential for tasks like robotic navigation and warehouse automation, where spatial positioning is important.

3. Polygon Annotation

Polygon annotation allows for more detailed labeling of objects with irregular shapes. Through granular shape recognition, this technique offers greater precision than bounding boxes. Such detailed precision is essential for the manufacturing industry, where even minor defects can compromise a product’s integrity. Thus, polygon annotation is ideal for detecting cracks in machinery, identifying oddly shaped components, and analyzing complex patterns in raw materials.

4. Temporal Annotation

This technique is used to label sequential data, such as video frames, to track changes over time. In manufacturing, temporal annotations are used to label manufacturing workflow sequences and sensor data timestamps. It monitors product flow across assembly lines, ensuring machinery operates within designated parameters, and analyzes worker movements to improve ergonomics.

5. Semantic Segmentation

Semantic segmentation involves labeling every pixel in an image or voxel in 3D point clouds to classify it into different categories. This technique is useful for high-resolution tasks in manufacturing, such as defect detection on highly detailed surfaces or monitoring equipment wear, where the exact area of a defect must be identified.

6. Audio Clip Annotation

As the name suggests, audio annotation involves labeling sound data to train models for audio-based applications, such as detecting machinery malfunctions through sound analysis. Audio recordings from equipment are transcribed into text and labeled with timestamps and machine sounds. By identifying patterns in audio signals, AI systems pinpoint irregularities indicative of equipment issues. Above all, it ensures compliance in noisy industrial environments.

As evident, data annotation in manufacturing is a significant undertaking. Even a minor error in annotations can lead to unreliable outcomes. In addition to reducing the AI application’s utility, a significant amount of effort and resources also go in vain. Thus, a smarter alternative is to outsource data annotation services. By doing so, manufacturers can ensure the quality and scalability of their AI/ML models while focusing on core competencies.

While data annotation is integral to AI's success in manufacturing, knowing the best practices is equally important. Especially for companies annotating datasets independently, it is essential to follow the best practices to maximize the effectiveness of data annotation in manufacturing.

Best Practices for Data Annotation in Manufacturing

- Define objectives clearly. Clearly define the objectives of the AI project before initiating the data annotation process. This ensures that annotations align with the intended use case and minimizes errors.

- Prioritize data quality. High-quality data is essential for training reliable AI models. Partnering with a reliable data annotation company helps ensure that datasets are accurately labeled.

- Leverage domain expertise. Involve subject matter experts to guide the annotation process. Their insights help identify critical features and anomalies that may not be apparent to generalist team members.

- Implement quality control practices. Review and validate annotations regularly to maintain accuracy. Incorporating automated quality checks can further streamline this process.

- Follow iterative refinement. AI models benefit from continuous learning and improvement. Periodically update and refine annotated datasets to incorporate new insights and evolving requirements.

Closing Lines

The integration of AI-powered applications in manufacturing has redefined the industry’s operational landscape, offering unprecedented levels of efficiency, precision, and safety. Central to this transformation is the role of data annotation, which lays the foundation of successful AI initiatives. By providing context to the raw data, annotations enable the AI systems to understand and interpret the data and perform actions such as predicting maintenance needs and identifying defects.

And, as the manufacturing industry continues to embrace digital transformation, investing in high-quality data annotation services will remain a critical enabler of AI-driven innovation.

Opinions expressed by DZone contributors are their own.

Comments