Big Data in Oil and Gas IIoT

With a modern IIoT and cloud platform underlying the next generation of applications and analytics, the oil and gas industry can move beyond just doing the same thing faster or cheaper and adopt new levels of productivity.

Join the DZone community and get the full member experience.

Join For FreeThe oil and gas industry was, at one time, at the forefront of Digital Transformation in industry. Nearly 50 years ago, it was the first industry to use digital distributed control systems (DCS) to control refineries and other downstream plants. Then, with the deployment of the digital oil field concept, it became a leader in adopting digital representations of seismic data representing deposits and reserves. The challenge for the industry now is to implement the next wave of Digital Transformation and radically shift the way it approaches Asset Performance Management (APM).

In some respects, as an early adopter of digital field instrumentation, the oil and gas industry has set itself up to potentially be late to the table when it comes to the next phase of Digital Transformation. A common refrain LNS Research often hears when talking to clients about the Industrial Internet of Things (IIoT) is the retort that nothing is new and that “we have been doing this for ages” because their companies have had sensors in place on all of their key processes. Similarly, the industry also serves as the breeding ground for data historians, so many hold parallel perceptions about their standing within analytics capabilities, opining, “we have been doing Big Data since the 80s, because we have a historian with 100,000 tags.”

Unfortunately, this too misses the real heart of Digital Transformation today that results from Big Data and predictive analytics, cloud technology and the IIoT. The convergence of these technology advances today will cause the “informationization” of industry, with changes as profound as industrialization did in the late 1700s. There will be a step-change in productivity similar to those that occurred with the advent of steam power, electrification, and then automation in the 1950s and ‘60s.

Big Data in Oil & Gas Is About More Than Just “Lots of Data”

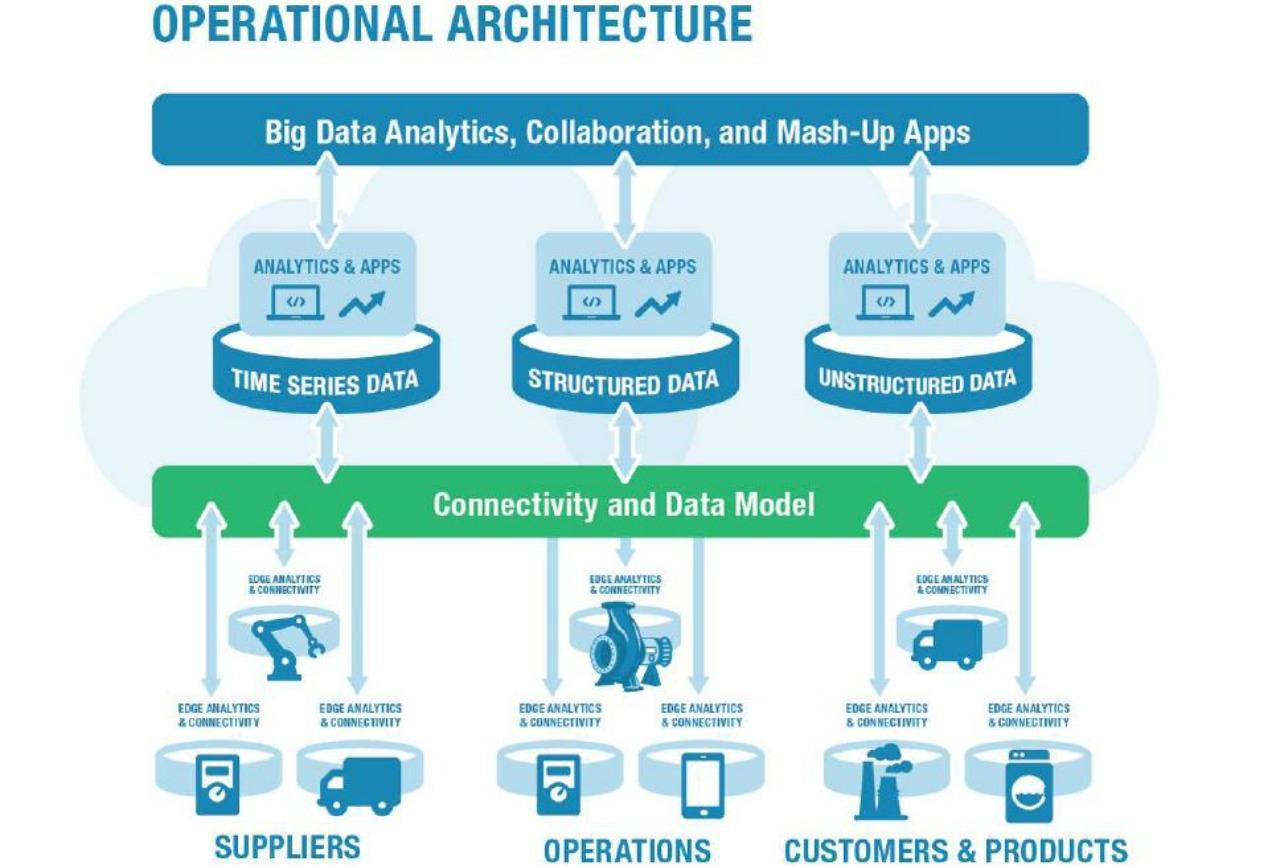

As IIoT technology becomes more prevalent, the amount and variety of information available about the condition of assets and the environment in which they are operating is growing exponentially. The industry, as an early adopter of process data historian technology, has been dealing with large volumes of time series information captured from the instrumentation that monitors and controls plant processes. While high in volume, this data is well structured, albeit simply indexed by time. Big Data, on the other hand, is far more varied, consisting of both structured and unstructured data. Examples include spectral data from vibration and thermography systems, textual descriptive information, and even potentially unrelated information about transitory events that may or may not be related. Making sense of this highly disjointed data is more complex than just extrapolating or interpolating from time series data that is highly correlated to the process itself.

The oil and gas industry has to manage risks on many fronts, and the assets employed are expensive and capital intensive. Any systems supporting the industry must be highly reliable, responsive and secure. Add to this equation the fact that many of the assets are geographically widely dispersed.

Existing model-based predictive algorithms work well with historical time series data, but not so well with Big Data. Cloud technology certainly becomes beneficial in handling the volumes and variability of Big Data. But to an even larger degree, advanced predictive methods with self-learning capabilities to use new and previously unknown or unavailable data will truly be the breakthrough technology that provides better insight into process and asset dynamics.

A Platform Approach Provides Critical Capabilities for Next Generation APM

The oil and gas industry has to manage risks on many fronts, and the assets employed are expensive and capital intensive. Any systems supporting the industry must be highly reliable, responsive and secure. Add to this equation the fact that many of the assets are geographically widely dispersed, and it becomes obvious that the computational resources to support the industry have greater demands than typical commercial computing platforms.

Responsiveness, reliability and security of cloud-based computing are essential. Losing connection to an email server for several seconds or waiting for a word processing document to update is acceptable; losing the connection to a high-pressure natural gas compressor to detect an impending problem isn’t. This is set against the backdrop of an industry that is facing some of the tightest economic margins ever. The ongoing cost of supporting a collection of disparate applications interfaced together isn’t feasible in the face of the current economic pressures in the industry.

Any solution must not only be affordable to deploy but economical to support for the foreseeable future. Fortunately, technology today can meet these demands. Advances in technology over the last five years have overcome all of the hurdles. What is needed now is confidence in the user community to leverage their own and their suppliers’ domain expertise to build and deploy the solutions that can turn the accessible data into actionable information. Predictive analytics helps us overcome the complexity of production today. The only thing holding the oil and gas industry back is resistance to cultural change. The first players that make the leap stand to gain a significant competitive edge.

Digital Transformation Can Revitalize Oil & Gas

With a modern IIoT and cloud platform underlying the next generation of applications and analytics, the oil and gas industry can move beyond just doing the same thing faster or cheaper and adopt new levels of productivity. The ability to base asset care decisions on financial criteria balances against sustainability, safety and operational risk management goals addresses the top concerns that industry leaders have identified in LNS Research’s APM, IIoT, and Business Demographics surveys, namely surviving in a more regulated and economically challenged environment.

Want to learn more about how the IIoT can transform oil and gas? Read how GE and BP are working together.

Related Refcard:

Published at DZone with permission of Dan Miklovic. See the original article here.

Opinions expressed by DZone contributors are their own.

Comments